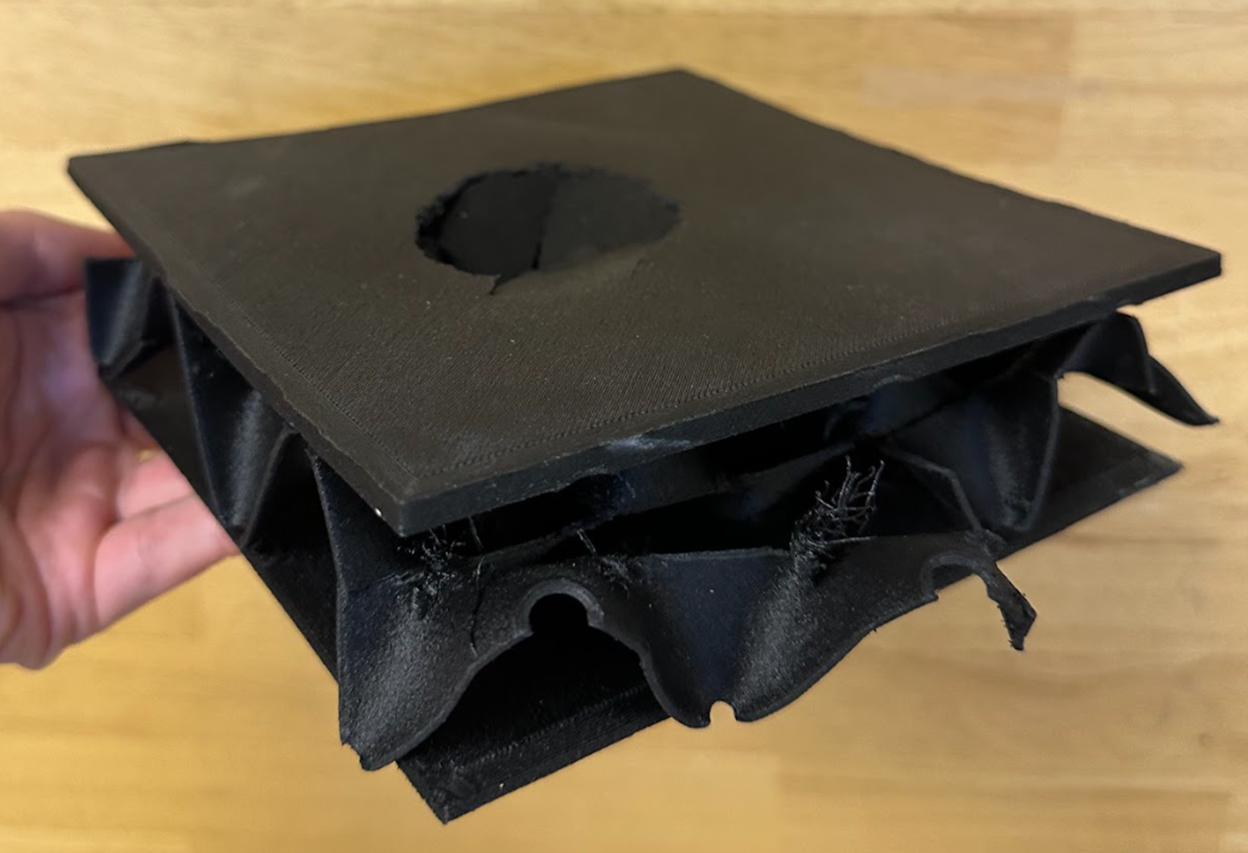

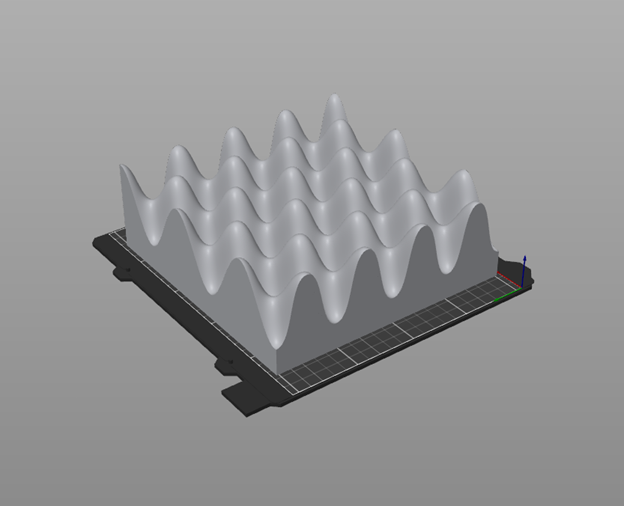

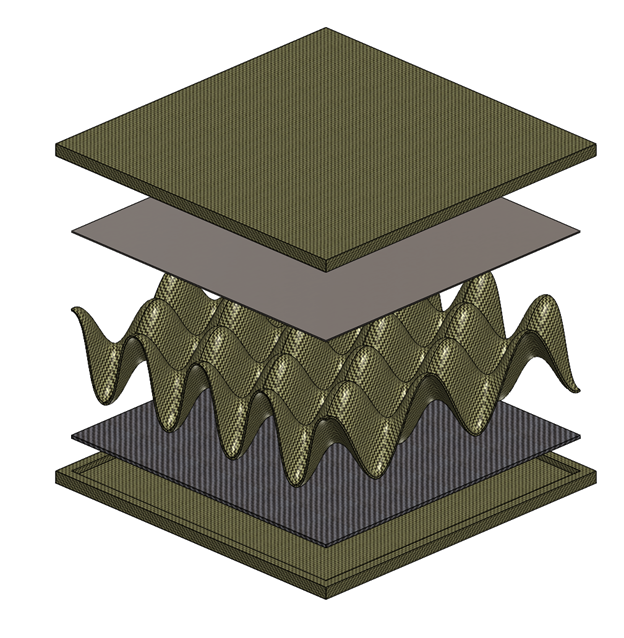

I conceptualized and designed an aircraft floorboard panel that utilizes a sinusoidal wave as its core, sandwiched between two layers of 90% infill Nylon Carbon Fiber.

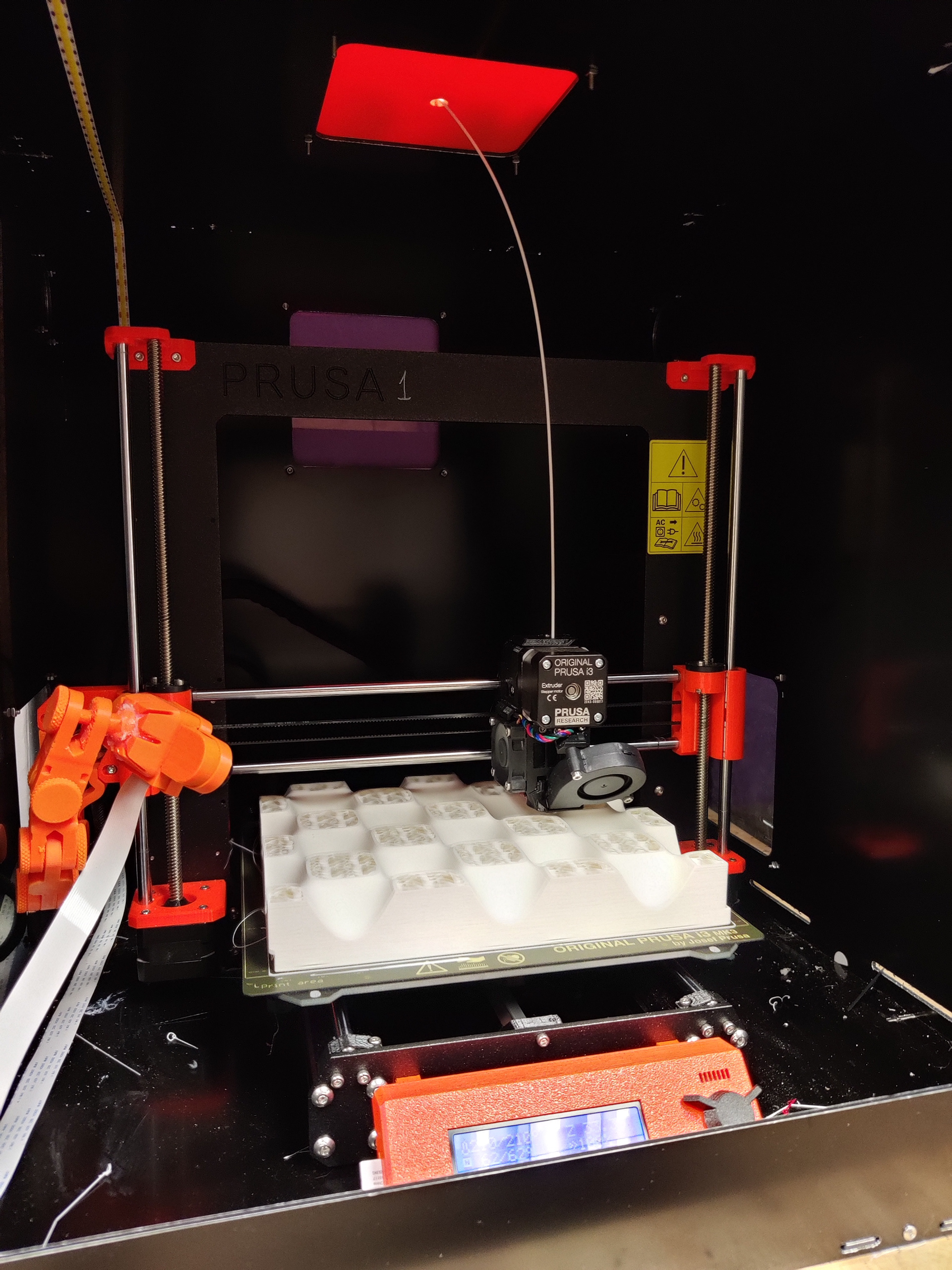

After testing the initial panel, I made modifications to the design and created a mold. The design was then handed over to a talented engineering team who used the mold to create a carbon fiber Kevlar prepreg core, resulting in a lightweight and strong aircraft floorboard panel.

The design objective was to redirect the vertical force applied to the panel into two principal stress planes. The final version of the panel, incorporating this core design, successfully met the project's established requirements.

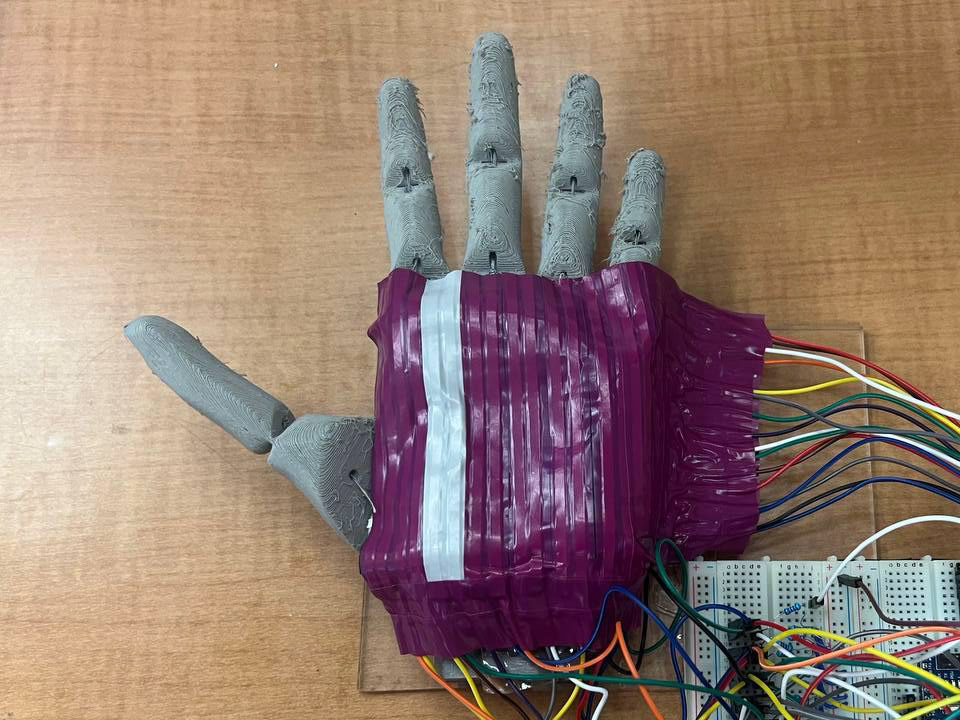

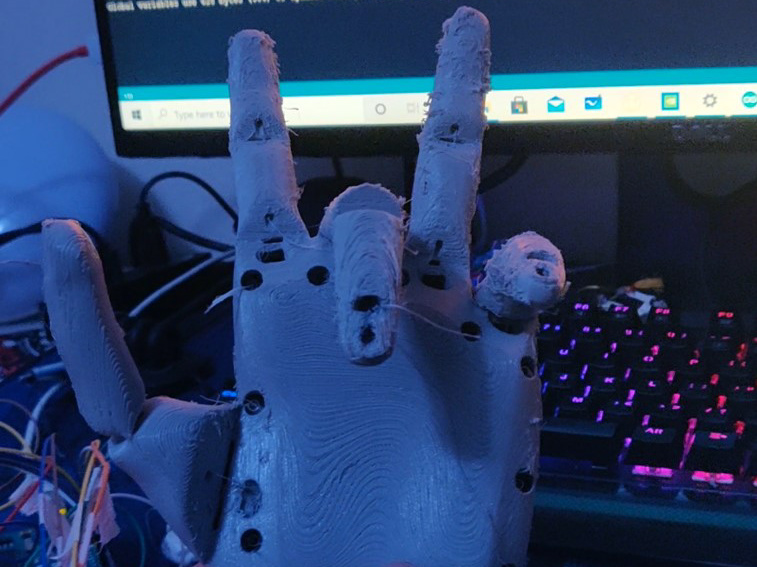

3D Printed Nylon CF Panel Post Drop Test

3D Printed Nylon CF Panel Post Drop Test

3D Printed Nylon CF Panel Post Drop Test

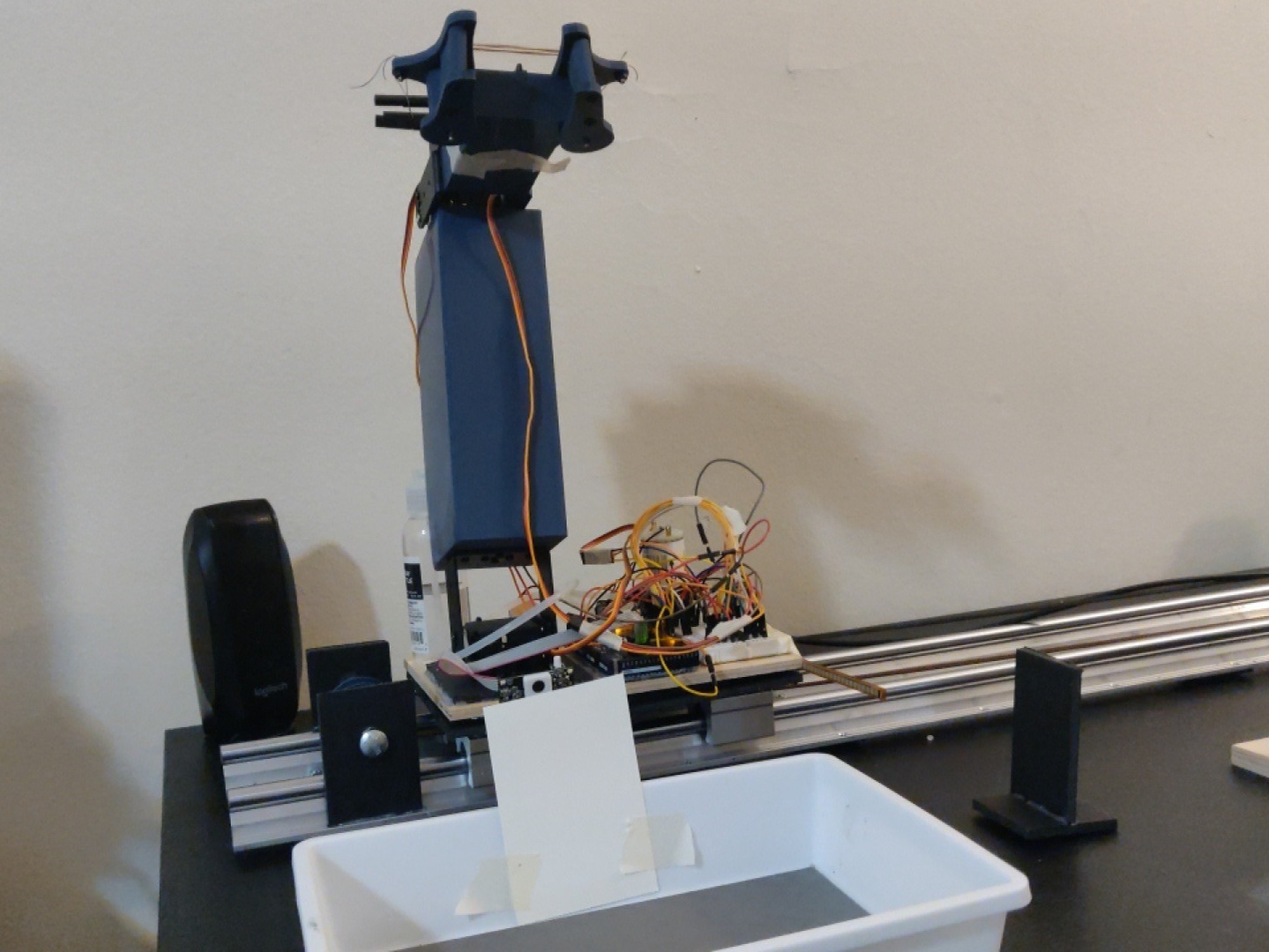

Mold for Sinusoidal Core

Final Panel Design Utilizing the Sinusoidal Core Design

3D Printing Molds for Sinusoidal Core

Drop Test on 3D Printed Nylon CF Panel